I used to think I could just stash my filament spools on a shelf and call it a day. It seemed simple: buy a roll of PLA, print whenever inspiration hit, and not sweat the details in between. But then the inevitable started happening—small inconsistencies, weird surface artifacts, and cracks in prints that seemed random. After digging a bit deeper, I finally connected the dots: my filaments were soaking up more moisture than I’d ever imagined.

In this guide, I’ll share some hard-learned lessons about storing and drying 3D printing filaments properly, so you won’t have to toss out spools or deal with the heartbreak of weak, stringy, or just plain messed-up prints. Along the way, we’ll talk about common DIY approaches, and why upgrading to a dedicated filament dry box—like the one from Kingroon—can seriously change your 3D printing life. We’ll also see how it pairs nicely with Kingroon Filaments, so you can focus on perfecting your designs instead of babysitting your spools.

Let’s get started!

What’s the Big Deal About Filament Storage?

When you’re new to 3D printing (or even if you’ve been doing it a while), it’s easy to underestimate the havoc that moisture can wreak on your filament. I know I did. All I could think about was bed leveling, retraction settings, flow rates—everything that happens in the printer itself. Meanwhile, my spools were hanging out in the open air, soaking up humidity like a thirsty sponge.

Most of our favorite materials—PVA, PA, TPU, Nylon, PETG, ABS, PLA and so on—are hygroscopic, meaning they absorb moisture from the environment. Leave them out in a humid room, or even a moderately damp one, and over time you’ll get filament that’s anything but fresh. The day you load it into your printer, you might wonder why you’re hearing little pops from the nozzle, or seeing weird strings everywhere, or even having the filament snap mid-print. That’s all moisture’s doing. It can ruin surface quality, reduce layer adhesion, and just generally make your prints look sad.

Symptoms of Soggy Filament

· Popping and Hissing: If your extruder sounds like popping, that’s steam escaping.

· Stringing, Blobs, and Oozing: Steam expansion can cause random blobs and threads.

· Rough Surface Finish: Moisture forms pockets that lead to surface bumps or tiny holes.

· Brittle Filament: Sometimes it gets so compromised it snaps just from unrolling.

source: 3dwithus.com

None of that is fun. Fortunately, once you know how crucial storage is, it’s not too hard to keep your filaments dry. Let’s run through a few options—ranging from super simple fixes to advanced solutions. And if you’re like me and prefer a “set it and forget it” approach, you’ll really want to hear about the filament dry box.

Basic Storage Hacks (a.k.a. The Quick Fixes)

Let’s be real: not everyone can (or wants to) drop money on specialized equipment right away. That’s okay. There are some quick fixes and DIY strategies you can try, especially if you’re only printing every so often. They might not be perfect, but they can extend your filament’s lifespan a bit.

Vacuum-Sealed Bags

You know how some filaments come vacuum-packed with little silica gel packets? Well, once you open them, you can try to re-seal them. It’s a bit fiddly to get all the air out if you don’t have a proper vacuum sealer, but even a tight Ziploc with extra desiccant is better than leaving your spool out in the open. Just remember that every time you open the bag for a new print, you’re letting in more moist air. Over time, it’ll be less effective.

Airtight Bins with Desiccant

Another low-cost method is using big plastic storage bins with rubber seals on the lid. Throw in some fresh silica gel packets (the bigger, the better) and store multiple spools inside. This method works decently well, but watch your humidity levels if you open the bin frequently. The more you open it, the more outside air you let in. After a while, you’ll need to refresh or recharge your silica gel because it’ll get saturated.

DIY Heater Boxes

Some folks convert a food dehydrator or a homebrew contraption into a filament dryer. If you can dial in a low, even temperature, this can definitely help remove moisture from a spool. The potential pitfall is uneven heat distribution or the risk of overheating your filament—especially if your contraption doesn’t have stable controls. Still, it’s an option if you’re on a budget and don’t mind tinkering.

Why You Might Want Something More Reliable

Let’s say you tried the bin-and-desiccant method for a while. Maybe it’s decent, but you’re tired of your once-fresh silica gel turning useless after a couple of spool swaps, or you keep forgetting to reseal your bag. If your printing volume is low, you might be okay. But if you print a lot or care a ton about consistent quality, maybe it’s time to up your game.

Moisture Happens (Especially in Humid Places)

Some people live in naturally drier climates. Others, not so much. If your area is prone to high humidity or big temperature swings, your filament absorbs moisture faster. Opening and closing containers all the time just speeds up the process. That’s why an active solution that removes moisture and keeps it away can be a sanity-saver.

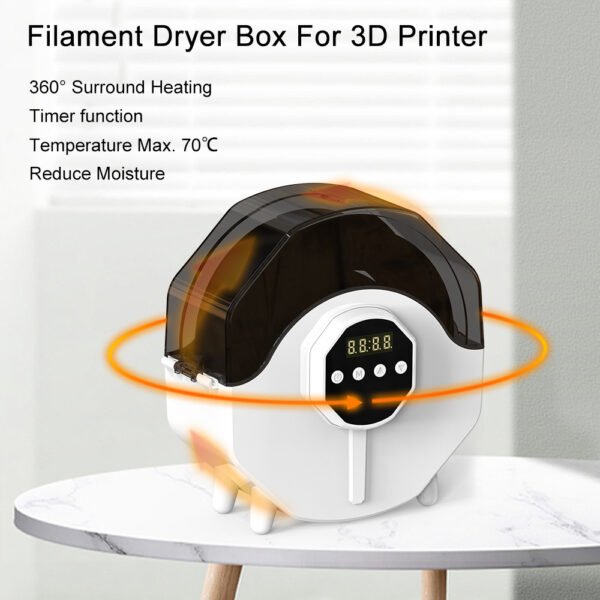

Meet the Kingroon 3D Filament Dry Box

If you’re already sick of babysitting spool containers and rummaging around for fresh desiccant, the Kingroon 3D Filament Dry Box is kind of a no-brainer. It’s basically a specialized box that actively heats and circulates air around your filament. And it’s sealed to keep humidity out.

Here’s what makes it stand out:

1. Built-In Heating: Low-level warmth (somewhere between 50–68°C) basically bakes off any absorbed moisture. Think of it like a spa day for your filament.

2. Internal Fan: The heat is circulated, so there aren’t hot spots or cold corners. Your spool gets even treatment throughout.

3. Timer and Standby Mode: You can set a drying time between 1–24 hours, so you won’t accidentally cook your filament for days on end. When time’s up, it goes into standby.

4. Print While Drying: This might be my favorite feature. You can feed the filament directly from the box to your printer, so it stays cozy and dry for the entire print. This is huge if you’re doing multi-day prints that would otherwise sit out in open air.

In other words, you just pop your spool in, set the temperature and duration, and go on about your business. No more guesswork or having to crack open a bin to see if you need more silica gel.

Pairing It with Kingroon Filaments

Now, you don’t have to restrict yourself to one specific brand of filament. The Kingroon Dry Box works fine with basically any spool. But you might ask: why do people often suggest using Kingroon’s filaments along with their dry box?

Synergy and Quality

For starters, Kingroon Filaments are known for their consistent diameter and good winding, which helps cut down on tangles or extrusion inconsistencies. They also offer a range of materials—PLA, PETG, TPU, Nylon, etc.—so no matter what projects you tackle, you’ll find something that fits. Pairing those spools with the brand’s own dry box means you can follow Kingroon’s recommended drying settings with less trial-and-error.

Stocking Up Without Worry

One of the best perks: if you see a killer bulk deal (like 10KG of PLA for $109), you can buy a bunch without worrying about it spoiling. The dry box helps you keep those big spools in great shape for months. You don’t have to feel rushed to use it all up right away. Store the spool inside the dryer whenever you’re not using it, and it’ll stay fresh until your next project.

Setting Up Your Dry Box Workflow

So, how do you work this new toy into your printing routine? It’s actually pretty straightforward:

1. Find a Spot: Put the dry box near your printer. You’ll want the filament path from box to extruder to be as short and friction-free as possible.

2. Load Your Spool: Pop open the box, place the spool on the holder, and thread the filament through the little exit port. Make sure the lid is sealed when you close it.

3. Pick Your Settings: For PLA, something around 50°C for a couple hours might be enough. If you’re dealing with heavily saturated filament (like PETG or Nylon that’s been left out for ages), you might go hotter or longer.

4. Wait (or Print Immediately): If you just want to store the spool at a lower heat or even no heat, that’s cool. If you need to actively remove moisture, crank up the temp for a set time.

5. Print On: If you’re ready to print, you can start your 3D printer and feed filament straight from the dry box. That way it never gets a chance to pick up moisture mid-print.

After your job finishes, you can just shut off the heat, leave the spool inside for storage, or pop in a new spool. Once you try it a few times, it becomes second nature.

My Personal Take on Why This Matters

I’ve had more than my fair share of bed-leveling nightmares, retraction experiments, and extruder swaps, but those headaches paled in comparison to dealing with soggy filament. It’s not just about print failures—it’s about random issues that pop up and completely throw off your game. You might waste an entire spool’s worth of material on repeated attempts before realizing humidity was the root cause.

Once I started using an actual dry box, it felt like a whole layer of random, unpredictable printing issues just vanished. Everything from stringing to surface finish to bed adhesion felt more consistent. It might sound dramatic, but it seriously improved my 3D printing life. Less wasted time, fewer scrapped prints, and no more rummaging for half-baked solutions.

Wrapping Up

At the end of the day, your filament is the one material you literally feed into your prints. If it’s compromised, no amount of slicer wizardry can truly fix the underlying problem. That’s why investing in proper storage is a big deal. Whether you go for a quick DIY method or upgrade to an active drying solution like the Kingroon 3D Filament Dry Box, you’ll thank yourself when you see those smooth, consistent layers forming on your printer.

And if you’re eyeing that big spool sale—like Kingroon’s 10KG PLA for $109—but wondering, “Will I ever use that much before it goes bad?” the answer is yes, you will. Because now you’ve got a plan to keep it fresh. You can literally print to your heart’s content, then pop the spool right back in the dry box for storage. No frantic rush to use it all at once. No regrets about buying in bulk.

In short, think of a filament dry box as the friend who makes sure you don’t leave your phone in the Uber or forget your keys on the kitchen counter. You’ll wonder how you ever got by without it. And your prints will become that much more reliable. So go forth, banish the moisture gremlins, and start printing with confidence. Because life’s too short for soggy filament.