Best Klipper 3D Printers in 2024: A Comprehensive Guide

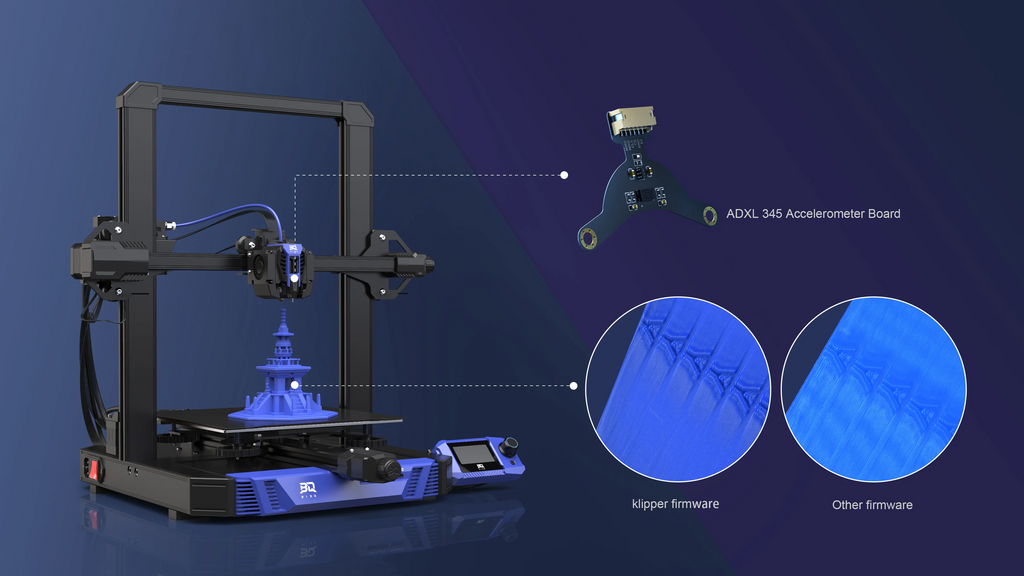

Klipper is an open-source firmware that enhances the performance and functionality of 3D printers. It uses a Raspberry Pi or another single-board computer to handle the complex calculations and commands for the printer, while the printer's mainboard acts as a simple interface. This allows Klipper to achieve faster printing speeds, higher accuracy, and more advanced features than traditional firmware.

In this article, we will explore the evolution of Klipper, from a DIY project to a pre-installed option on some of the best 3D printers in 2024. We will also look at the rise of Klipper in the 3D printing community, and how it has influenced the design and development of new printers. Finally, we will review some of the most popular and reliable printers that come with factory-installed Klipper, and compare their features, pros, and cons.

Evolution of Klipper: From DIY to Pre-Installed

Klipper was created by Kevin O'Connor in 2014, as a way to improve the performance of his 3D printer. He released the source code on GitHub, and soon other enthusiasts started to use and contribute to the project. Klipper gained popularity among the DIY 3D printing community, especially those who wanted to experiment with different hardware and software configurations.

One of the early adopters of Klipper was the Voron project, a group of 3D printer enthusiasts who designed and built their own CoreXY printers. The Voron printers are known for their high speed, quality, and reliability, and they use Klipper as their default firmware. The Voron project also helped to develop and improve some of the features of Klipper, such as input shaping, pressure advance, and multiple microcontroller support.

As Klipper continued to evolve and prove its reliability, it caught the attention of various 3D printer manufacturers. They began to offer it as either an alternative or the default firmware on their products. This trend expanded rapidly, and by 2024, Klipper was available on a wide spectrum of 3D printers, ranging from budget-friendly options to high-end models.

The Rise of Klipper in the 3D Printing Community

Klipper has become one of the most popular and widely used firmware in the 3D printing community, thanks to its many advantages and benefits. Some of the reasons why Klipper has gained so much popularity are:

Speed

Klipper can achieve faster printing speeds than traditional firmware, by offloading the complex calculations to a more powerful computer. This reduces the load on the printer's mainboard, and allows it to execute commands more efficiently and smoothly.

Accuracy

Klipper can improve the accuracy and quality of the prints, by using advanced algorithms and features to compensate for the physical limitations and imperfections of the printer. For example, Klipper can use input shaping to reduce the ringing and ghosting effects caused by the inertia of the printer's moving parts. Klipper can also use pressure advance to adjust the extrusion rate according to the speed and direction of the nozzle, and prevent over- or under-extrusion.

Features

The most popular feature of Klipper is certainly its ability to increase the speed of the 3D printer. In addition, Klipper can offer more features and functionality than traditional firmware by leveraging the power and flexibility of the Raspberry Pi or another single-board computer. For example, Klipper can also use Fluidd, Mainsail or KlipperScreen to provide a graphical user interface and touchscreen support for the printer.

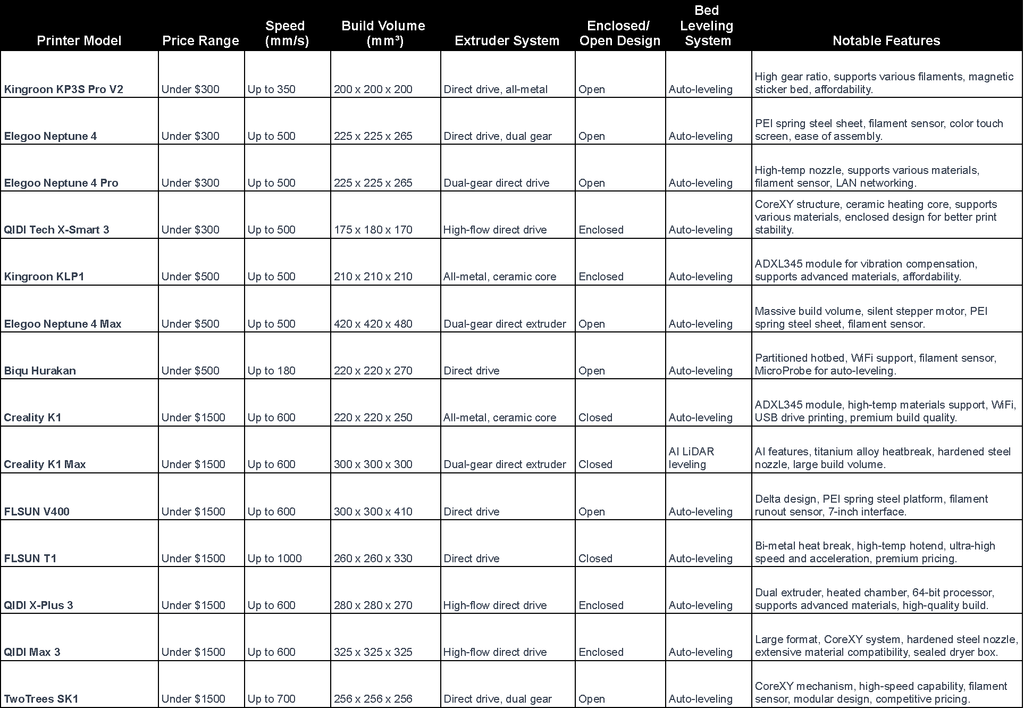

Pre-Installed Klipper 3D Printers

In this section, we will review some of the best 3D printers that come with factory-installed Klipper in 2024. We will compare their features, pros and cons, and help you choose the best one for your needs and budget. The chart below summarizes the printers we will cover in the article:

Overview of 3D Printers with Klipper Pre-Installed

Budget-Friendly Options (under $300)

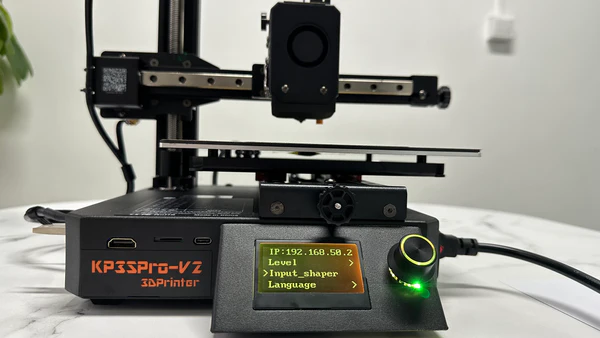

Kingroon KP3S Pro V2: An Overview

The Kingroon KP3S Pro V2 is a 3D printer that comes with Klipper firmware installed, which allows it to achieve high printing speeds and accuracy. It has a direct drive extruder with a ceramic heater and a 9.5:1 gear ratio, which enables it to handle various types of filaments. It also has linear rails on all three axes, which make it more stable and durable. The printer has a build volume of 200 x 200 x 200 mm, and supports Wi-Fi, and USB drive printing. The price of the printer is $279, which makes it an affordable option for hobbyists and enthusiasts.

Figure 1 source: kingroon.com

Features, Pros, and Cons of Kingroon KP3S Pro V2

The Kingroon KP3S Pro V2 has many features that make it a competitive 3D printer in the market. Some of the pros and cons of the printer are:

Speed and Acceleration

The printer can print at a maximum speed of 350 mm/s and a maximum acceleration of 10,000 mm/s². It also has an accelerometer built-in for input shaper calibration, which reduces the ringing and ghosting effects caused by the inertia of the printer's moving parts. This makes the printer suitable for fast and high-quality printing.

Build Volume

The printer has a build volume of 200 x 200 x 200 mm, which is sufficient for most hobby and personal projects. However, it may not be enough for larger or more complex models.

Extruder System

The printer has an all-metal extruder with a ceramic heating tube and a 9.5:1 gear ratio. This makes the extruder strong and fast, and able to handle a variety of materials and temperatures. The extruder also supports auto-leveling and fast heating.

Compatible Materials

The printer can print with different types of filaments, such as PLA, PETG, TPU, and more. It has a nozzle diameter of 0.4 mm and a temperature range of 180 - 300°C.

Enclosed vs. Open Design

The printer has an open design, which means it does not have a cover or a door to enclose the printing area. This makes it easier to access and monitor the printer, but it also exposes it to external factors, such as dust, humidity, and temperature changes. An open design may also affect the print quality of some materials, such as ABS, that require a stable and warm environment.

Bed Leveling System

The printer has an auto bed leveling system, which means it can automatically adjust the distance between the nozzle and the bed to ensure a consistent first layer. The bed is made of aluminum and has a magnetic sticker on top. The bed can heat up to 100°C. The bed leveling system works well without any first layer issues, and the magnetic sticker makes it easy to remove the prints.

Ease of Assembly and Maintenance

The printer is easy to assemble and maintain, as it comes with a detailed manual and a video guide. The printer has linear rail guides on all axes, which make it more stable and durable.

Firmware

The printer uses Klipper firmware which achieves faster printing speeds, higher accuracy, and more advanced features than traditional firmware.

Price

The printer costs $279 on the official website of Kingroon but it is currently available for a discounted rate of $229. It is also available on other online platforms, such as Amazon and AliExpress, but the price may vary depending on the seller and the shipping options. The price of the printer is affordable, considering the features and specifications it offers.

Elegoo Neptune 4

The Elegoo Neptune 4 is a budget-friendly 3D printer that offers outstanding performance and user-friendly design. It is an upgraded version of the Neptune 3 Pro, with the main difference being the use of Klipper firmware, which allows the printer to reach higher speeds and achieve better accuracy. The Neptune 4 also features a direct drive extruder, a dual Z-axis, a PEI spring steel sheet, a filament runout sensor, and a color touch screen. It is easy to assemble and maintain, and can print with a variety of materials, including PLA, PETG, and TPU.

Figure 2 source: matterhackers.com

Features, Pros, and Cons of Elegoo Neptune 4

The Elegoo Neptune 4 distinguishes itself from other 3D printers through a variety of features. Here are some of the advantages and disadvantages of this printer:

Speed and Acceleration

The Neptune 4 can print up to 500 mm/s, thanks to the Klipper firmware which enables the printer to handle complex movements and input shaping, resulting in smoother and faster prints. However, the Klipper firmware is hidden from the user, and requires a LAN connection or a compatible WiFi dongle to access its settings and features.

Build Volume

The Neptune 4 has a build volume of 225 x 225 x 265 mm, which is slightly larger than the average for its price range. It can print large models or multiple smaller ones at once, giving the user more flexibility and creativity.

Extruder System

The Neptune 4 has a direct drive extruder, which means the filament is fed directly into the hotend, without the need for a Bowden tube. This reduces the friction and retraction issues, and improves the print quality and reliability. The extruder also has a dual gear mechanism, which ensures a strong grip and a consistent feed rate of the filament. The hotend has a high flow nozzle, which can reach up to 300 degrees Celsius, allowing the printer to handle high-temperature materials.

Compatible Materials

The Neptune 4 can print with a wide range of materials, such as PLA, PETG, TPU, ABS, and more. The direct drive extruder and the high flow nozzle make it especially suitable for flexible and abrasive materials, such as TPU and carbon fiber. The heated bed can reach up to 110 degrees Celsius, which helps with the adhesion and warping of the prints. The printer also comes with a PEI textured spring steel sheet, which provides a smooth and durable surface for the prints to stick to, and can be easily removed and flexed to release the prints.

Enclosed vs. Open Design

The Neptune 4 has an open design, which means it does not have a cover or a door to enclose the printing area. This has some advantages and disadvantages, depending on the user’s preferences and needs. On the one hand, an open design makes it easier to access and monitor the prints, and allows for better cooling and ventilation. On the other hand, an open design exposes the prints to the ambient temperature and humidity, which can affect the print quality and stability, especially for materials that are sensitive to these factors, such as ABS. An open design also makes the printer louder and less safe, as the moving parts and the hot components are not shielded from the user or the environment.

Bed Leveling System

The Neptune 4 has an automatic bed leveling system, which uses a sensor to measure the distance between the nozzle and the bed at several points, and adjusts the Z-offset accordingly. This saves the user time and hassle, and ensures a consistent and accurate first layer.

Filament Sensor

The Neptune 4 has a filament runout sensor, which detects when the filament is about to run out or break, and pauses the print automatically.

Ease of Assembly and Maintenance

The Neptune 4 is very easy to assemble and maintain, as it comes 90% pre-assembled, and only requires the user to attach the gantry to the base, and connect a few cables and screws. The assembly process takes about 15 minutes, and the instructions are clear and simple. The maintenance of the printer is also straightforward, as the components are well-organized and accessible.

Firmware

The Neptune 4 uses Klipper firmware. However, the Neptune 4 does not make full use of the Klipper firmware, as it hides it from the user, and does not provide a Klipper screen or a WiFi module to access its settings and features. The user has to connect the printer to a LAN network or a compatible WiFi dongle, and use a web interface or an app to control the Klipper firmware. This makes the firmware less user-friendly and limits the user’s ability to customize and optimize the printer.

Price

The Neptune 4 is priced at $229, which is very affordable for a 3D printer with such features and performance. It is one of the cheapest 3D printers that use Klipper firmware, and offers a great value for money. However, the user may have to spend some extra money to buy a WiFi dongle or a Klipper screen, if they want to access the full potential of the Klipper firmware.

Elegoo Neptune 4 Pro

The Elegoo Neptune 4 Pro is a new addition to the Elegoo family of 3D printers, following the Neptune 4. It features a dual-gear direct drive extruder, a 300°C high-temp nozzle, and an intelligent segmented heatbed. It supports a variety of materials, such as PLA, PETG, ABS, TPU, Nylon, and more. It also has a pre-installed Klipper firmware, which allows for faster and smoother printing, auto bed leveling, and LAN networking. The Elegoo Neptune 4 Pro has a print volume of 225 x 225 x 265 mm³ and a maximum printing speed of 500 mm/s.

Figure 3 source: tomshardware.com

Features, Pros, and Cons of Elegoo Neptune 4 pro

The Elegoo Neptune 4 Pro sets itself apart from its counterparts in the 3D printing market with a range of unique attributes. Below are the pros and cons associated with this printer:

Speed and Acceleration

One of the main selling points of the Elegoo Neptune 4 Pro is its impressive speed and acceleration. Thanks to the Klipper firmware the printer can achieve speeds up to 500 mm/s and accelerations up to 20,000 mm/s². This means that the printer can finish large and complex prints in a fraction of the time compared to other FDM printers. However, the speed and acceleration also depend on the material, layer height, and print quality settings, so users may need to adjust them accordingly to avoid artifacts and errors.

Build Volume

The Elegoo Neptune 4 Pro has a decent build volume of 225 x 225 x 265 mm³. This allows users to print bigger and taller models, such as helmets, vases, sculptures, and more.

Extruder System

The Elegoo Neptune 4 Pro features a dual-gear direct drive extruder. A direct drive extruder has the advantage of having less filament path and less friction, which results in better extrusion control, less retraction, and less stringing. A dual-gear extruder also has the benefit of having more grip and torque on the filament, which enables the printer to handle flexible and abrasive materials better. The extruder also has a 300°C high-temp nozzle, which can print materials that require higher temperatures, such as ABS, Nylon, and ASA.

Compatible Materials

The Elegoo Neptune 4 Pro is compatible with a wide range of materials, thanks to its direct drive extruder and high-temp nozzle. It can print common materials, such as PLA and PETG, as well as more advanced materials, such as ABS, TPU, Nylon, ASA, and more. However, some materials may require additional settings and modifications, such as a heated enclosure to ensure optimal print quality and adhesion.

Enclosed vs. Open Design

The Elegoo Neptune 4 Pro has an open design, which means that it does not have a fully enclosed chamber or a cover. This has some pros and cons, depending on the material and the environment. On one hand, an open design allows for better airflow and cooling, which is beneficial for materials that are prone to warping and cracking, such as PLA and PETG. It also allows for easier access and maintenance of the printer. On the other hand, an open design exposes the printer to external factors, such as dust, humidity, and temperature fluctuations, which can affect the print quality and reliability.

Bed Leveling System

The Elegoo Neptune 4 Pro has an intelligent segmented heatbed, which consists of 121 (11 x 11) points that can be individually calibrated. This allows for automatic bed leveling, which is a convenient feature that eliminates the need for manual adjustment and ensures a flat and even printing surface. The heatbed also has a removable magnetic surface, which makes it easy to remove the prints and clean the bed.

Filament Sensor

The Elegoo Neptune 4 Pro has a filament sensor, which is a useful feature that detects the presence and movement of the filament. This helps to prevent print failures due to filament runout, jamming, or tangling.

Ease of Assembly and Maintenance

The Elegoo Neptune 4 Pro is easy to assemble and maintain, as it comes in a semi-assembled kit that only requires a few steps and screws to complete. The assembly process takes about 15 to 30 minutes, and the printer comes with a detailed instruction manual and a video tutorial. The maintenance of the printer is also simple, as it has a modular design that allows for quick and easy replacement of parts.

Firmware

The Elegoo Neptune 4 Pro has a pre-installed Klipper firmware. The Klipper firmware allows for LAN networking, which enables users to connect the printer to a local network and control it remotely via a web interface or an app.

Price

The Elegoo Neptune 4 Pro has a competitive price of $279.00, which is slightly higher than the Neptune 4, but still affordable for most hobbyists and enthusiasts.

QIDI Tech X-Smart 3

The Smart 3 is a 3D printer that offers high speed, and versatile material compatibility. It is designed to be easy to use, maintain, and customize. The Smart 3 features a CoreXY structure, a direct drive extruder, a heated bed, a filament sensor, and an open-source firmware.

Figure 4 source: ar.geekbuying.com

Features, Pros, and Cons of QIDI Smart 3

Speed and Acceleration

The Smart 3 can print at speeds up to 500 mm/s and accelerations up to 20000 mm/s², thanks to its CoreXY mechanics and Klipper firmware. This allows for faster and smoother prints, especially for complex models and large objects.

Build Volume

The QIDI Smart 3 has a build volume of 175 x 180 x 170 mm, which is slightly smaller than the average 3D printer. However, this size is still enough to print most models and parts. The printer also has a double-sided flexible magnetic HF plate that allows for easy removal of prints.

Extruder System

The Smart 3 has a high-flow direct drive extruder that can handle a wide range of materials, including PLA, ABS, ASA, PETG, TPU, and more. The extruder has a ceramic heating core and a brass nozzle that can reach temperatures up to 300°C. The extruder also has a 9.5:1 transmission ratio, which ensures precise and consistent extrusion.

Compatible Materials

The Smart 3 can print with most of filament types, thanks to its high-temperature extruder and heated bed. The heated bed can reach temperatures up to 120°C, which helps with adhesion and warping prevention.

Enclosed vs. Open Design

The QIDI Smart 3 has an enclosed design that protects the print from dust, noise, and external factors. The enclosure also helps maintain a consistent temperature and humidity inside the chamber, which improves print quality and reliability.

Bed Leveling System

The Smart 3 has an automatic bed leveling system that measure the distance between the nozzle and the bed. The system then adjusts the Z-axis accordingly to ensure a level and uniform print surface.

Filament Sensor

The Smart 3 has a filament sensor that detects the presence and movement of the filament. The sensor pauses the print and alerts you when the filament runs out or breaks, so you can replace it and resume the print without losing your progress.

Ease of Assembly and Maintenance

The Smart 3 comes pre-assembled and ready to print within 10 minutes.

Firmware

The Smart 3 runs on Klipper firmware, which allows for faster and smoother printing, as well as more customization and optimization options.

Price

The Smart 3 is priced at around $299, which is a reasonable price for its features and performance.

Mid-Range Models (under $500)

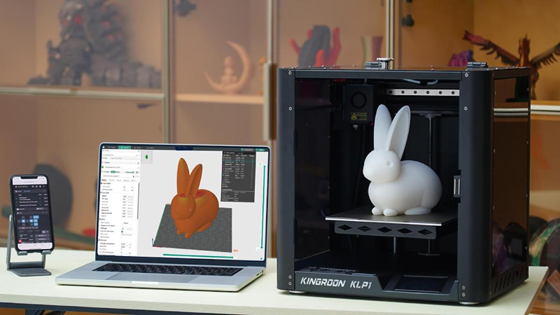

Kingroon KLP1

The Kingroon KLP1 is a CoreXY 3D printer that comes with a protective enclosure and Klipper firmware installed. It has a maximum printing speed of 500 mm/s and a maximum acceleration of 10,000 mm/s², thanks to the built-in ADXL345 module that enables active vibration compensation. It also has an all-metal extruder with a ceramic heating core and a 5:1 gear ratio, which allows it to print with various types of filaments, including high-temperature materials. The printer has a build volume of 210 x 210 x 210 mm, and supports Wi-Fi, and USB drive printing. The price of the printer is $379 with current discounts as low as $339, which makes it one of the most affordable fast 3D printers supporting advanced material printing such as ABS and ASA out of the box.

Figure 5 source: finance.yahoo.com

Features, Pros, and Cons of Kingroon KLP1

The Kingroon KLP1 has many features that make it stand out among other 3D printers. Some of the pros and cons of the printer are:

Speed and Acceleration

The printer can print at a maximum speed of 500 mm/s and a maximum acceleration of 10,000 mm/s², which makes it one of the fastest 3D printers in the market. It also has an accelerometer built-in for input shaper calibration, which reduces the ringing and ghosting effects caused by the inertia of the printer's moving parts. This makes the printer suitable for fast and high-quality printing.

Build Volume

The printer has a build volume of 210 x 210 x 210 mm, which is large enough for most projects. However, it may not be enough for some users who need to print bigger or more complex models.

Extruder System

The printer has an all-metal extruder with a ceramic heating core and a 5:1 gear ratio. This makes the extruder strong and fast, and able to handle a variety of materials and temperatures.

Compatible Materials

The printer can print with different types of filaments, such as PLA, ABS, PETG, TPU, and more. It also supports high-temperature materials, such as nylon and CF, thanks to its all-metal hotend and ceramic heating core. It has a nozzle diameter of 0.4 mm and a temperature range of 180 - 260°C.

Enclosed vs. Open Design

The printer has an enclosed design, which means it has a cover and a door to enclose the printing area. This helps to maintain a stable and warm environment for the print, and prevent warping and cracking of some materials, such as ABS. It also reduces the noise and odor of the printer, and protects it from dust and moisture. However, the enclosure does not have a dedicated heating system, which means it relies on the heat generated by the printer itself. This may not be enough for some materials that require higher temperatures, such as polycarbonate.

Bed Leveling System

The printer has an auto bed leveling system, which means it can automatically adjust the distance between the nozzle and the bed to ensure a consistent first layer. The bed is made of aluminum and has a magnetic sticker on top.

Ease of Assembly and Maintenance

The printer is easy to assemble and maintain, as it comes with a detailed manual and a video guide. The printer has linear rail guides on all three axes, which make it more stable and durable.

Firmware

The printer uses Klipper firmware, which is an open-source firmware that enhances the performance and functionality of 3D printers.

Price

The printer costs $379 on the official website of Kingroon, but it is available for as low as $339 right now with a special discount available on the website. It is also available on other online platforms, such as Amazon and AliExpress, but the price may vary depending on the seller and the shipping options. The price of the printer is reasonable, considering the features and specifications it offers.

Elegoo Neptune 4 Max: Overview

The Elegoo Neptune 4 Max is a fast and large FDM 3D printer that offers a range of features and capabilities for enthusiasts and professionals alike. It has a massive build volume of 420 x 420 x 480 mm, a top printing speed of 500 mm/s, and a high-temperature nozzle that can reach up to 300°C. It also supports various filaments, has a dual-gear direct extruder, and has a 11x11 auto leveling system. The printer runs on the Klipper firmware, which allows for faster and smoother printing performance. The Elegoo Neptune 4 Max is a versatile and powerful 3D printer that can handle complex and large-scale projects with ease.

Figure 6 source: all3dp.com

Features, Pros, and Cons of Elegoo Neptune 4 Max

Speed and Acceleration

One of the most impressive features of the Elegoo Neptune 4 Max is its speed and acceleration. The printer can achieve a maximum printing speed of 500 mm/s and an acceleration of 8,000 mm/s², which is much faster than most FDM 3D printers on the market. This means that the printer can finish large prints in a shorter time, without compromising on quality or accuracy. The printer also has a silent stepper motor driver, which reduces the noise and vibration during printing.

Build Volume

Another notable feature of the Elegoo Neptune 4 Max is its huge build volume of 420 x 420 x 480 mm, which is one of the largest among FDM 3D printers. This allows the printer to print large models or multiple parts at once, without the need for splitting or scaling.

Extruder System

The Elegoo Neptune 4 Max has a dual-gear direct extruder system, which provides a stable and precise extrusion of the filament. The extruder has a high-temperature nozzle that can reach up to 300°C.

Compatible Materials

The Elegoo Neptune 4 Max is compatible with a wide range of filaments, thanks to its high-temperature nozzle and direct extruder system. The printer can print with common materials, such as PLA and TPU, as well as more advanced materials, such as PETG, ABS, ASA, and Nylon. The printer also supports flexible and composite filaments, such as wood, carbon fiber, and metal.

Enclosed vs. Open Design

The Elegoo Neptune 4 Max has an open design, which means that the printer does not have a fully enclosed chamber or cover. This has some advantages and disadvantages, depending on the type of filament and the printing environment.

Bed Leveling System

The Elegoo Neptune 4 Max has a 11x11 auto leveling system, which means that the printer can automatically adjust the distance between the nozzle and the bed, based on 121 measuring points. This ensures that the bed is level and flat, which is essential for a good first layer and a successful print.

Filament Sensor

The Elegoo Neptune 4 Max has a filament sensor, which detects the presence and movement of the filament. The filament sensor can alert the user when the filament is about to run out or break, and pause the print until the user replaces the filament.

Ease of Assembly and Maintenance

The Elegoo Neptune 4 Max is easy to assemble and maintain, as it comes in three pre-assembled parts: the base, the gantry, and the screen. The user only needs to connect the parts with a few screws and cables, and follow the instructions on the manual or the video.

Firmware

The Elegoo Neptune 4 Max runs on the Klipper firmware, The Klipper firmware allows the printer to achieve faster and smoother printing performance.

Price

The Elegoo Neptune 4 Max is priced at $470, which is a reasonable price for a fast and large FDM 3D printer. The printer also comes with a one-year warranty and lifetime support from Elegoo.

Biqu Hurakan

The Biqu Hurakan is a 3D printer that runs on Klipper firmware. The printer has a metal frame, a direct drive extruder, a MicroProbe for auto-leveling, and a partitioned hotbed for power saving. It also supports wireless printing via WiFi and has a filament sensor to pause the print when the filament runs out.

Figure 7 source: biqu3d.com

Features, Pros, and Cons of QIDI Smart 3

Speed and Acceleration

The printer can reach a printing speed of up to 180 mm/s, thanks to the Klipper firmware that calculates the motion of the printer in advance and sends commands to the stepper motors in real time. The acceleration is also adjustable via the web interface or the LCD screen.

Build Volume

The printer has a build volume of 220 x 220 x 270 mm, which is large enough for most projects. The hotbed is divided into two zones. This allows the user to print on a smaller area and save energy, or print on the whole area for larger models.

Extruder system

The printer has a direct drive extruder, which means the filament is pushed directly into the hotend without a bowden tube. This reduces the friction and improves the extrusion accuracy and quality. The extruder also has a dual-gear mechanism that grips the filament firmly and prevents slipping or grinding.

Compatible Materials

The printer can print with a variety of materials, such as PLA, ABS, PETG, TPU, and more. The hotend can reach a maximum temperature of 260°C, and the hotbed can reach 100°C. The printer also has a cooling fan and a silicone sock to keep the temperature stable and prevent clogging or oozing.

Enclosed vs. Open Design

The printer has an open design, which means it does not have a cover or a door to enclose the printing area. This makes it easier to access and monitor the print, but also exposes it to the ambient temperature and humidity, which may affect the print quality and adhesion. Some users may prefer to add an enclosure to the printer, especially when printing with materials that are sensitive to warping or cracking, such as ABS.

Bed Leveling System

The printer has a microprobe, a sensor that detects the distance between the nozzle and the bed. The microprobe is attached to the extruder and moves with it, so it can measure the bed level at multiple points. The printer then compensates for any unevenness by adjusting the Z-axis during the print.

Filament Sensor

The printer has a filament sensor, a device that detects the presence and movement of the filament. The sensor is located near the extruder and can pause the print when the filament runs out or breaks.

Ease of Assembly and Maintenance

The printer comes in a semi-assembled kit, which means the user has to assemble some parts by following the instructions and videos provided by the manufacturer. The assembly process is not very difficult, but it may take some time and patience. The maintenance of the printer is also relatively easy, as the user only needs to clean the nozzle, the bed, and the fans regularly, and lubricate the rods and bearings occasionally.

Firmware

The printer runs on Klipper firmware, which allows the printer to achieve faster and smoother printing, as well as more features and customization options. The user can access and control the printer via a web interface or an LCD screen.

Price

The printer costs around 389 US dollars, which is a reasonable price for its features and performance.

Premium Selections (Under $1500)

Creality K1: An Overview

The Creality K1 is a CoreXY 3D printer that comes with Klipper firmware installed, which allows it to achieve high printing speeds and accuracy. It has a maximum printing speed of 600 mm/s and a maximum acceleration of 20,000 mm/s², thanks to the built-in ADXL345 module that enables active vibration compensation. It also has an all-metal extruder with a ceramic heating core which allows it to print with various types of filaments, including high-temperature materials. The printer has a build volume of 220 x 220 x 250 mm, and supports Wi-Fi, and USB drive printing. The price of the printer is $599, which makes it a competitive option for fast and high-quality printing.

Figure 8 source: all3dp.com

Features, Pros, and Cons of Creality K1

The Creality K1 has many features that make it stand out among other 3D printers. Some of the pros and cons of the printer are:

Speed and Acceleration

The printer can print at a maximum speed of 600 mm/s and a maximum acceleration of 20,000 mm/s², which makes it one of the fastest 3D printers in the market. It also has an accelerometer built-in for input shaper calibration, which reduces the ringing and ghosting effects caused by the inertia of the printer's moving parts.

Build Volume

The printer has a build volume of 220 x 220 x 250 mm, which is sufficient for most hobby and personal projects.

Extruder System

The printer has an all-metal extruder with a ceramic heating core. This makes the extruder strong and fast, and able to handle a variety of materials and temperatures. The extruder also supports auto-leveling and fast heating. However, some users have reported that the extruder was noisy and prone to clogging.

Compatible Materials

The printer can print with different types of filaments, such as PLA, ABS, PETG, TPU, and more. It also supports high-temperature materials, such as nylon and CF, thanks to its all-metal hotend and ceramic heating core. It has a nozzle diameter of 0.4 mm and a temperature range of 180 - 300°C.The printer has a filament sensor, which means it can detect when the filament runs out or breaks, and pause the print accordingly.

Enclosed vs. Open Design

The printer has a closed design. This helps to maintain a stable and warm environment for the print.

Bed Leveling System

The printer has an auto bed leveling system, which means it can automatically adjust the distance between the nozzle and the bed to ensure a consistent first layer. The bed is made of aluminum and has a magnetic sticker on top. The bed can heat up to 100°C and has a size of 220 x 220 mm.

Ease of Assembly and Maintenance

The printer is easy to assemble and maintain, as it comes with a detailed manual and a video guide.

Firmware

The printer uses Klipper firmware that enhances the performance and functionality.

Price

The printer costs $599 on the official website of Creality. It is also available on other online platforms, such as Amazon and AliExpress, but the price may vary depending on the seller and the shipping options.

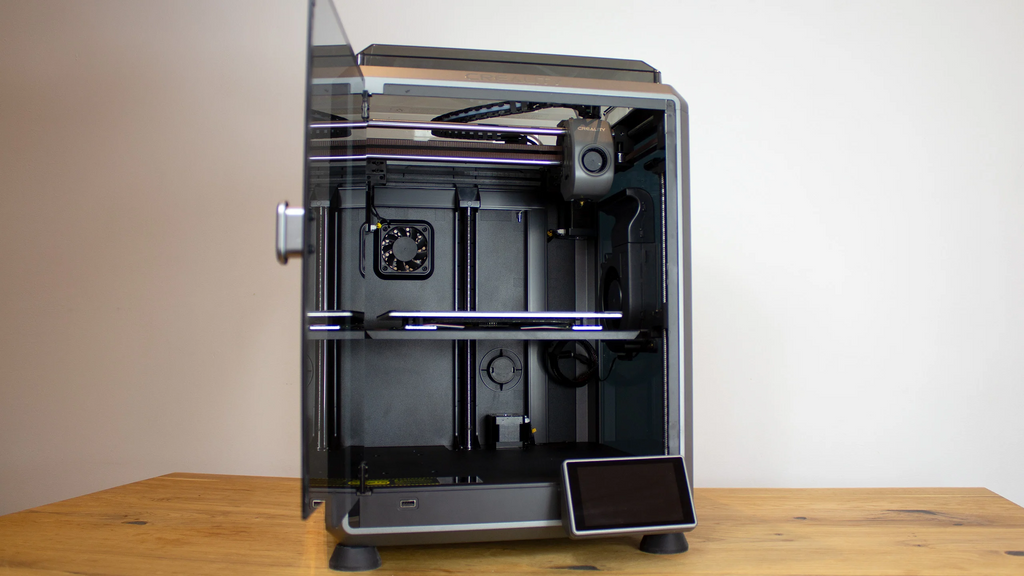

Creality K1 max 3D printer: an Overview

The Creality K1 max is a high-speed FDM 3D printer that can reach 600mm/s in only 0.03s and has a large build volume of 300x300x300mm. It has smart features such as AI LiDAR, AI camera, dual-gear direct extruder.

Figure 9 source: all3dp.com

Features, Pros, and Cons

The Creality K1 max is a remarkable 3D printer with various advantages and disadvantages. Here are some of them:

Speed and Acceleration

The K1 max combines the nimble Core XY with a 190g lightweight printhead for less motion inertia. It also has a new ceramic heater, a titanium alloy heatbreak, and a hardened steel nozzle that enable a maximum flow of 32mm³/s . with printing speed of 600mm/s the K1 max can print up to 12 times faster than regular 3D printers.

Build Volume

The K1 max boasts a 300x300x300mm large build volume, great for rapid prototyping or design verification. It also offers a high build volume to printer size ratio of 25.5%. The K1 max is the most size-efficient FDM 3D printer in its class.

Extruder System

The K1 max features a dual-gear direct extruder that delivers strong extrusion force and reduces the risk of clogging and filament slipping. The extruder also supports flexible filaments such as TPU and TPE.

Compatible Materials

The K1 max can print with a wide range of materials, such as PLA, ABS, PETG, Nylon, Wood, Carbon Fiber, and more. The hotend can work well in up to 300℃, allowing for high-temperature materials. The heated bed can reach 100℃, ensuring good adhesion and preventing warping.

Enclosed vs. Open Design

The K1 max has a closed design that can improve the printing quality and stability for some materials, such as ABS and Nylon. The enclosure also reduces noise and dust.

Bed Leveling System

The K1 max uses an AI LiDAR to scan the first layer and automatically adjust the bed level. The LiDAR has a 1 μm resolution and can detect any errors or deviations in the first layer.

Filament Sensor

The K1 max has a filament sensor that can detect the end of the filament or any breakage. The sensor will pause the printing and alert the user to change the filament. The printing can then resume from where it left off.

Ease of Assembly and Maintenance

The K1 max is easy to assemble and maintain, as it comes with a unibody frame that is sturdy and stable. The assembly process only requires a few steps and tools. The maintenance is also simple, as the K1 max has a modular design that allows for quick replacement of parts.

Firmware

The K1 max runs on the smart Creality OS, which features a straightforward UI and syncs data and commands with PC, phone, Cloud, and add-on modules.

Price

The K1 max is priced at around $899.00, which is competitive for its performance and features. The price may vary depending on the seller and the region.

FLSUN V400

The FLSUN V400 is a delta 3D printer that offers high speed and quality prints with the help of Klipper. The printer has a direct drive extruder, a PEI spring steel build platform, a filament runout sensor, and a 7-inch Speeder Pad interface. The printer has a massive height of 45 inches and a cylindrical build volume of 300 x 300 x 410 mm

Figure 10 source: flsun.eu

Features, Pros, and Cons of FLSUN V400

Speed and Acceleration

One of the main selling points of the FLSUN V400 is its speed and acceleration. The printer can print at a speed of 600 mm/s. The printer achieves this speed with the help of Klipper.

Build Volume

The printer has a large build volume of ⌀300 x 410 mm. This means that the printer can handle large and complex models without compromising on speed or quality. However, the printer also has a massive height of 45 inches, which may pose some challenges for placement and transportation.

Extruder System

The printer has a direct drive extruder, which means that the motor is mounted directly on the hotend, reducing the distance between the filament and the nozzle. This allows for better control and accuracy, especially for flexible materials like TPU.

Compatible Materials

The printer can print with a variety of materials, such as PLA, PETG, TPU, and ABS. The printer has a bi-metal heat break that can handle temperatures up to 300°C, allowing for high-temperature materials like ABS. However, the printer does not have an enclosed design, which may affect the print quality and stability of some materials, especially ABS.

Enclosed vs. Open Design

The printer has an open design, which means that it does not have a cover or a chamber to enclose the printing area.

Bed Leveling System

The printer has a bed leveling system that uses a detachable probe to measure the distance between the nozzle and the bed at several points. The printer then adjusts the height of the nozzle accordingly to compensate for any unevenness or tilt of the bed. The bed leveling system is easy to use and reliable, ensuring a good first layer and a smooth print surface.

Filament Sensor

The printer has a filament sensor that detects when the filament runs out or breaks during printing. The printer then pauses the print and alerts the user, allowing them to change the filament and resume the print without losing the progress or quality.

Ease of Assembly and Maintenance

The printer comes partially assembled, with the main components already pre-wired and pre-configured. The user only needs to assemble the frame, the spool holder, which can be done in about 20 minutes with the help of the manual and the tools provided

Firmware

The printer uses Klipper as its firmware, which is an alternative to the standard Marlin firmware that most 3D printers use.

Price

The printer has a price of $699. However, the printer also offers some features and benefits that justify its price, such as the speed, the quality, the build volume.

FLSUN T1

The FLSUN T1 is a delta 3D printer that boasts ultra-high speed and performance. It is designed to print large and complex models with high accuracy and stability. The T1 features a direct-drive extruder, a bi-metal heat break, and a hotend combo that can handle temperatures up to 300°C. The T1 also comes with Klipper firmware.

Figure 11 source: 3dprintingperth.com

Features

Speed and Acceleration

One of the main selling points of the T1 is its impressive speed and acceleration. The T1 claims to have a maximum print speed of 1000 mm/s, an acceleration of 30000 mm/s², and a volumetric flow rate of 90 mm³/s. These numbers are among the highest in the market, and they enable the T1 to print large models in a fraction of the time compared to other printers. However, such high speeds also require careful tuning and calibration, as well as high-quality filament and cooling.

Build Volume

The T1 has a spacious build volume of ⌀260 mm x 330 mm. The T1 also has a heated bed that can reach up to 110°C, which helps with adhesion and prevents warping.

Extruder System

The T1 has a direct-drive extruder, which means that the motor is mounted directly on the hotend, rather than on the frame. This reduces the distance between the filament and the nozzle, which improves the extrusion accuracy and reduces the risk of clogging or jamming. The T1 also has a bi-metal heat break, which is a metal tube that connects the heat sink and the heater block. The bi-metal heat break has two different metals with different thermal conductivities, which creates a sharp temperature gradient and prevents heat creep.

Compatible Materials

The T1 can print with a wide range of materials, thanks to its high-temperature hotend and heated bed. The T1 can handle PLA, ABS, PETG, TPU, Nylon, PC, and more. The T1 also has a filament runout sensor, which detects when the filament is about to end and pauses the print, allowing the user to change the spool and resume the print.

Enclosed vs. Open Design

The T1 3D printer features a closed design, incorporating a cover and a door that encloses the printing area.

Bed Leveling System

The T1 has an automatic bed leveling system which measure the distance between the nozzle and the bed at several points. The T1 then compensates for any unevenness or tilt of the bed by adjusting the Z-axis accordingly. This ensures that the first layer is consistent and adheres well to the bed.

Firmware

The T1 comes with Klipper firmware, which allows for faster and smoother printing.

Price

The T1 is priced at $599, which is a quite affordable price for high-speed 3D printers.

QIDI X-Plus 3

The QIDI Plus 3 is a high-speed 3D printer designed for professional applications and advanced materials. The QIDI Plus 3 features a fully upgraded all-metal frame, a CoreXY structure, a heated chamber, a dual extruder system, and a 64-bit processor with Klipper firmware. It can print at speeds up to 600 mm/s, with a high flow rate of 35 mm³/s and an acceleration of 20000 mm/s². It has a large build volume of 280 x 280 x 270 mm, and can print with a variety of materials, including PLA, ABS, PETG, Nylon, Carbon Fiber, and more.

Figure 12 source: eu.qidi3d.com

Features, Pros, and Cons of QIDI X-Plus 3

Speed and Acceleration

One of the main selling points of the QIDI Plus 3 is its impressive speed and acceleration, which make it suitable for fast and efficient printing of large and complex models. The QIDI Plus 3 uses Klipper firmware, which offloads the motion planning from the microcontroller to the 64-bit processor, resulting in smoother and faster movements. The printer is equipped with TMC2209 silent drivers, which reduce the noise and vibration of the motors. The QIDI Plus 3 can print at speeds up to 600 mm/s, with a high flow rate of 35 mm³/s and an acceleration of 20000 mm/s².

Build Volume

The QIDI Plus 3 has a large build volume of 280 x 280 x 270 mm, which allows it to print bigger and taller models than most of its competitors

Extruder System

The QIDI X-Plus 3 features a compact direct drive printhead and a high-flow direct drive extruder.

Compatible Materials

The QIDI Plus 3 can print with a wide variety of materials, thanks to its high-temperature hot ends, heated chamber, and flexible bed. The printer can print with standard materials, such as PLA, PETG, or TPU, as well as advanced materials, such as ABS, Nylon, Carbon Fiber, Wood, Metal, or PVA. The printer can also print with flexible materials, such as TPE or TPU, which require a direct drive extruder.

Enclosed vs. Open Design

The QIDI Plus 3 has an enclosed design, which means that it has a metal frame and a transparent cover that enclose the printing area. The enclosed design has several advantages, such as maintaining a stable temperature inside the chamber, reducing the noise and odor of the printing process.

Bed Leveling System

The QIDI Plus 3 has an automatic bed leveling system, which uses Klipper adaptive meshing and purging to ensure a flawless first layer for every print. The printer probes the bed at several points, and creates a mesh that compensates for any unevenness or tilt of the bed. The printer also purges the nozzle before each print, to avoid any oozing or clogging.

Ease of Assembly and Maintenance

The QIDI Plus 3 is easy to assemble and maintain, as it comes mostly pre-assembled and calibrated. The user only needs to install the extruder, the filament holder, and the cover, and connect the cables, which takes about 15 minutes. The printer also comes with a detailed user manual, a quick start guide, and a video tutorial, which guide the user through the assembly and the first print. The printer also comes with a toolkit, a spare parts box, and a filament box, which include everything the user needs to start printing and to perform basic maintenance.

Firmware

The QIDI Plus 3 uses Klipper firmware, which has several advantages over traditional firmware, such as faster and smoother motion planning, better print quality, more customization options.

Price

The QIDI Plus 3 is priced at $629.00.

QIDI Max 3

The QIDI Max 3 is a large-format 3D printer that offers fast printing speeds, high-quality prints, and a wide range of compatible materials. It is an upgraded version of the QIDI X-Max, with improved features such as a dual Z-axis, a hardened steel nozzle, and a Klipper firmware. The QIDI Max 3 is suitable for hobbyists, professionals, and anyone who loves tinkering with 3D printing.

Figure 13 source: eu.qidi3d.com

Features, Pros, and Cons of QIDI Max 3

Speed and Acceleration

The QIDI Max 3 can print at a maximum speed of 600 mm/s and an acceleration of 20000 mm/s², thanks to its CoreXY motion system and the Klipper firmware. This allows for faster and smoother prints, especially for large and complex models.

Build Volume

The QIDI Max 3 has a generous build volume of 325 x 325 x 325 mm, which is one of the largest among FDM 3D printers. This enables users to print big and detailed models without compromising on quality.

Extruder System

The QIDI Max 3 features a high-flow direct drive extruder with a 9.5:1 transmission ratio and a ceramic heating core. The extruder can reach temperatures up to 350°C, which is ideal for printing with high-temperature materials. The QIDI Max 3 also comes with a copper alloy nozzle and a hardened steel nozzle, which are interchangeable and can handle abrasive filaments.

Compatible Materials

The QIDI Max 3 can print with a variety of materials, including PLA, ABS, PETG, TPU, Nylon, PC, Carbon Fiber, and more. The printer also has a sealed print dryer box and a desiccant dryer to keep the filament dry and prevent moisture-related issues. The printer supports 1.75 mm filament diameter and has a filament sensor to detect the end of the filament and pause the print.

Enclosed vs. Open Design

The QIDI Max 3 has an enclosed design with a removable top lid and a front door. The enclosure helps to maintain a stable temperature inside the chamber, which is beneficial for printing with materials that are prone to warping and cracking. The enclosure also reduces noise and dust, and protects the print from external factors. The printer has an independent chamber heating system that can reach up to 65°C, and a chamber circulation fan with an activated carbon air filter to remove odors and harmful gases.

Bed Leveling System

The QIDI Max 3 has an automatic bed leveling system that uses a sensor to measure the distance between the nozzle and the bed. The printer then adjusts the Z-offset accordingly to ensure a consistent and accurate first layer. The printer also has a double-sided flexible magnetic HF plate that can be easily detached and bent to remove the prints. The plate can withstand temperatures up to 120°C and has a good adhesion to various materials.

Ease of Assembly and Maintenance

The QIDI Max 3 comes pre-assembled and ready to print out of the box. Users only need to connect the power cord, the filament, and the leveling sensor, and then follow the instructions on the touchscreen to set up the printer.

Firmware

The QIDI Max 3 runs on the Klipper firmware. The Klipper firmware can handle complex calculations and commands faster and more efficiently than traditional firmware, resulting in higher print speeds, better print quality, and more customization options.

Price

The QIDI Max 3 is priced at around $899, which is reasonable for a 3D printer with such impressive features and performance.

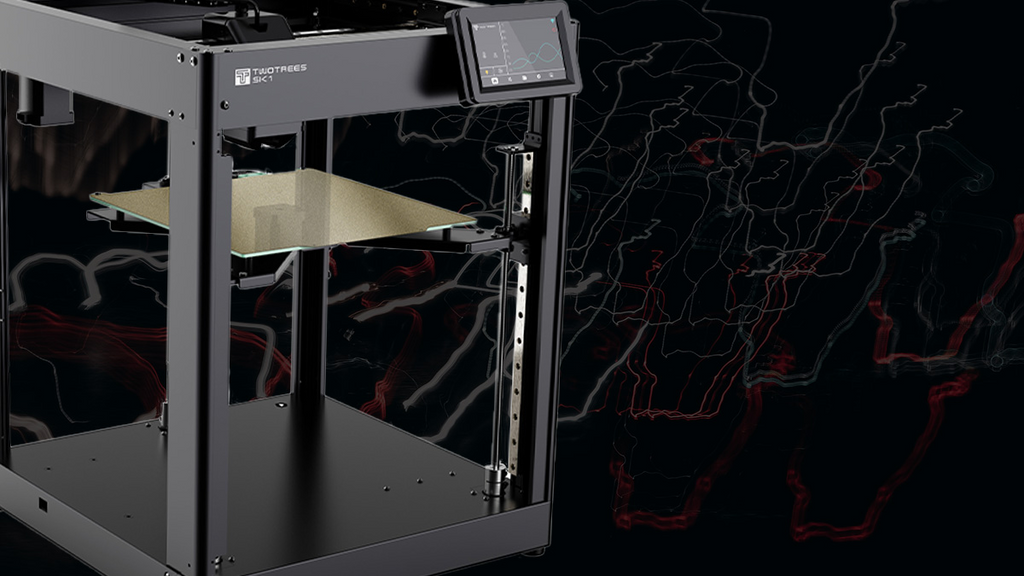

TwoTrees SK1

The TwoTrees SK1 is a CoreXY 3D printer that boasts impressive speed and accuracy. It is based on the Klipper firmware, which allows it to achieve up to 700 mm/s of print speed. The SK1 also has other practical features, such as self-calibration, filament sensor, and a sturdy structure. The SK1 is a great choice for enthusiasts who want to print fast and reliably.

Figure 14 source: all3dp.com

Features, Pros, and Cons of TwoTrees SK1

Speed and Acceleration

The SK1’s main selling point is its speed and acceleration. The printer uses a CoreXY mechanism, which reduces the moving mass and increases the stability of the print head. The SK1 can print up to 700 mm/s, which is much faster than most FDM printers on the market. However, speed comes at a cost of quality, and users may need to tweak the settings to find the optimal balance.

Build Volume

The SK1 has a decent build volume of 256 x 256 x 256 mm, which is enough for most projects. The printer has a heated bed, which can reach up to 100°C.

Extruder System

The SK1 has a direct drive extruder, which means the filament is fed directly into the hotend, without the need for a Bowden tube. This reduces the friction and improves the extrusion consistency and quality. The printer also has a dual-gear extruder, which provides more torque and grip on the filament. The hotend can reach up to 300°C, and has a 0.4 mm nozzle, which can be replaced with other sizes.

Compatible Materials

The SK1 can print with a variety of materials, such as PLA, ABS, PETG, TPU, and more. The direct drive extruder and the heated bed make it easier to print with flexible and high-temperature materials. However, some materials may require an enclosure to prevent warping and cracking, which the SK1 does not have by default.

Enclosed vs. Open Design

The SK1 has an open design, which means it does not have a cover or a door to enclose the printing area. This has some advantages and disadvantages. On the one hand, an open design makes it easier to access and monitor the printer, and allows better cooling and ventilation. On the other hand, an open design exposes the printer to dust, noise, and temperature fluctuations, which can affect the print quality and reliability.

Bed Leveling System

The SK1 has a self-calibration system, which uses a sensor to probe the bed and adjust the Z-offset automatically. This makes the bed leveling process much easier and faster, and eliminates the need for manual adjustments. The printer also has a dual Z-axis, which ensures the stability and precision of the bed leveling.

Filament Sensor

The SK1 has a filament sensor, which detects the presence and movement of the filament. This feature can prevent print failures due to filament runout or jamming, and can pause the print and resume it after the problem is solved. The filament sensor is located near the extruder, which makes it more accurate and responsive.

Ease of Assembly and Maintenance

The SK1 comes in a semi-assembled kit, which requires some assembly and wiring. The assembly process is not very difficult, and the instructions are clear and detailed. The printer also comes with some spare parts and tools, which can be useful for maintenance and troubleshooting. The printer has a modular design, which makes it easy to access and replace the components.

Firmware

The SK1 runs on the Klipper firmware, which is an open-source firmware that offloads the motion planning to a Raspberry Pi, instead of the printer’s microcontroller. This allows the printer to achieve higher speeds and smoother movements, as well as more features and customization options. The Klipper firmware can be controlled via a web interface, which is convenient and user-friendly.

Price

The SK1 is priced at around $575, which is a reasonable price for its features and performance. The printer offers a lot of value for money.

Klipperize your old 3D printer

You can add Klipper to most 3D printers that are currently running Marlin firmware, which is the most common firmware for 3D printers. To do so, you will need a Raspberry Pi, a USB cable, and a microSD card. You will also need to install some software on your Raspberry Pi and your printer’s mainboard.

One of the guides that can help you with this process is this one: How to Install Klipper on Ender 3. It provides detailed instructions and screenshots on how to set up Klipper on your Ender 3 printer. However, you can also follow this guide for other 3D printers that use Marlin firmware, as the steps are very similar.

Conclusion

Klipper firmware has changed the world of 3D printing a lot. It went from a small project to a big feature in many top 3D printers. This guide shows how Klipper makes printers work better, no matter if they are cheap or expensive. Printers with Klipper can print faster and more accurately. It's also great because people can add Klipper to their old printers, making them better without spending too much. This shows that Klipper is a big deal in making 3D printing better for everyone.