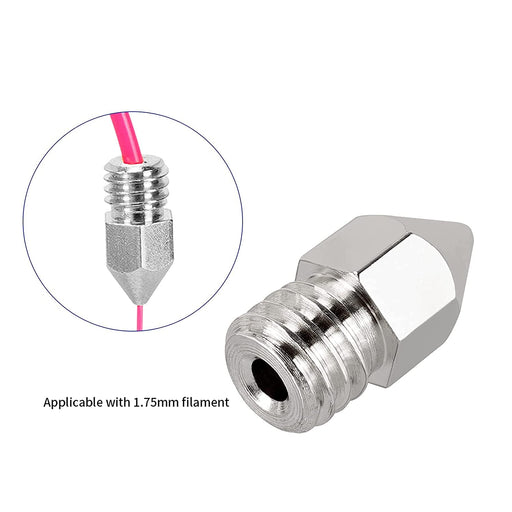

Tungsten Carbide Nozzle volcano Super Wear-Resistance DLC coating for rapido hotend

1. Super Wear-Resistance | The Tungsten Carbide Nozzle Uses the world's leading ultra-high hardness tungsten carbide (hardness > 2700Hv (up to 2900Hv)), super wear resistance ensures long-term printing without weariness of nozzle hole and tip flat.

2. High-Temperature Performance | Composed of tungsten carbide and copper alloy with super hardness and excellent conductivity, the maximum printing temperature can be 550℃

3. Low Pushing Force | Tungsten Carbide Nozzle with high purity of more than 99.98% and high thermal performance keeps an even temperature of nozzle tip during printing, thus guaranteeing a stable extrusion.

4. Faster Speed | Due to the high thermal performance of the nozzle in general, the printing speed can be pushed even further without sacrificing the quality. A unique passageway in the nozzle improves the flow rate at the inner hole faster.

5. Low Friction | The whole nozzle is applied with DLC coating after adding a hard and smooth nickel plating layer. The surface friction coefficient is as low as 0.05 which makes the nozzle with clean printing, without plastic sticking to it.

Material:

1. Nozzle is tungsten carbide

2. The body is copper alloy with nickel plating + DLC (hardened).

DLC coating:

1. The friction coefficient is only 0.05, effectively avoiding molten plastic sticking to the nozzle;

2.Coating thickness 2.0μm, without effects on any dimension accuracy;

3. Maintaining good lubrication and wear resistance up to 300℃;

4. Strong adsorption capacity, coating hardness HV2200;

5. Stable chemical properties, non-toxic, non-corrosive, and insoluble in other solvents.