Recently, we have heard a complaining, saying that we should not set the default retraction speed at 90mm/s while the Bambu Lab set it 30mm/s, I take it seriously and tested about it.

Results come first. The retraction speed doesn’t affect stringing so much, 30mm/s and 90mm/s give no big difference on stringing issues. But for Bowden tube 3D printers, we still need to test it and see if there are any differences.

For KINGROON 3D printers, we use direct drive extruder mostly. It is more precise and have better performance while printing with dual or tri color filaments. Direct drive extruder keeps the filament stable, so that the color won’t change angles on your prints.

Base on the direct drive extruder, I usually set the retraction distance as 1-2mm, the speed as 90mm/s. The retraction distance is one of the most important settings for reducing stringing. If the distance is too long, you might get constant clogged nozzle issue. If it is too short, you might get stringing on your prints.

Alright, let’s see the test.

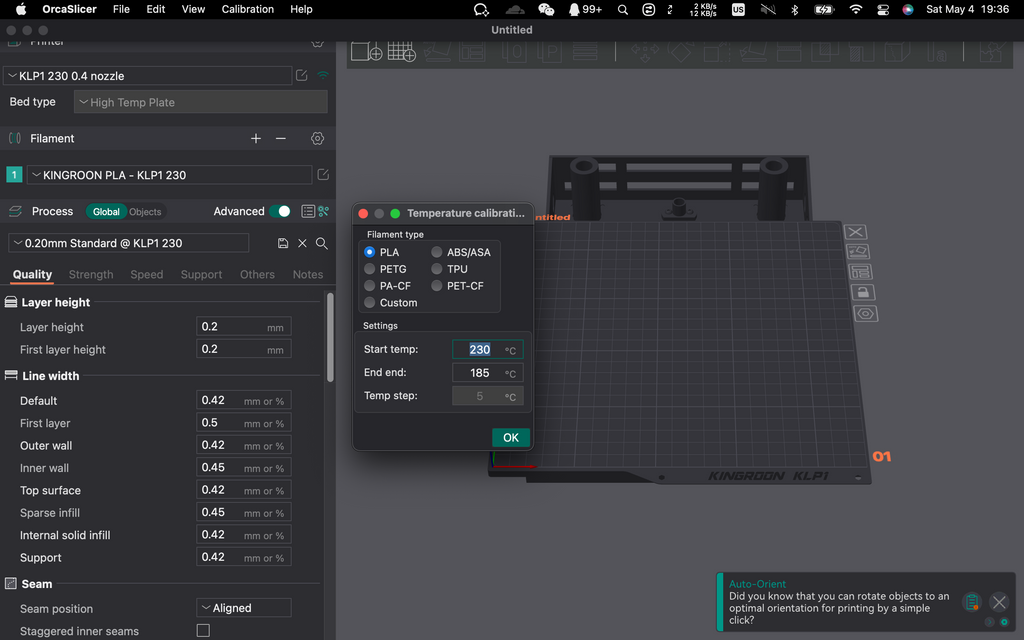

Prepare Test

Since the temperature is another most important thing for reducing stringing, I printed a temperature tower first. You can learn more about this test in OrcaSlicer Calibration, the Final Puzzle for KINGROON KLP1 and KP3S Pro V2

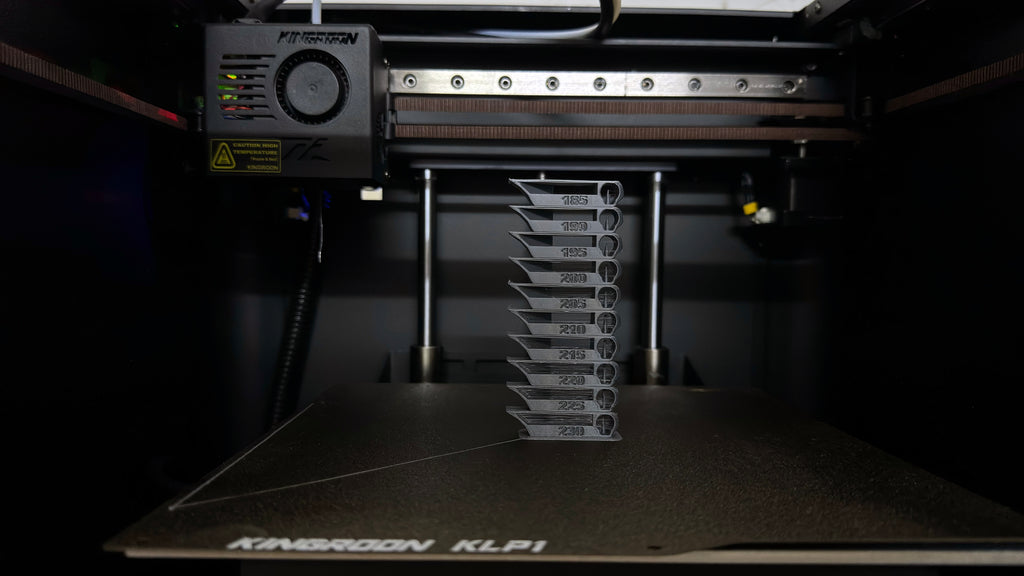

Temperature Tower

As the tower shows, the best temperature is 185-190. Since that period have almost no stringing, the ideal test temperature is 195 -205.

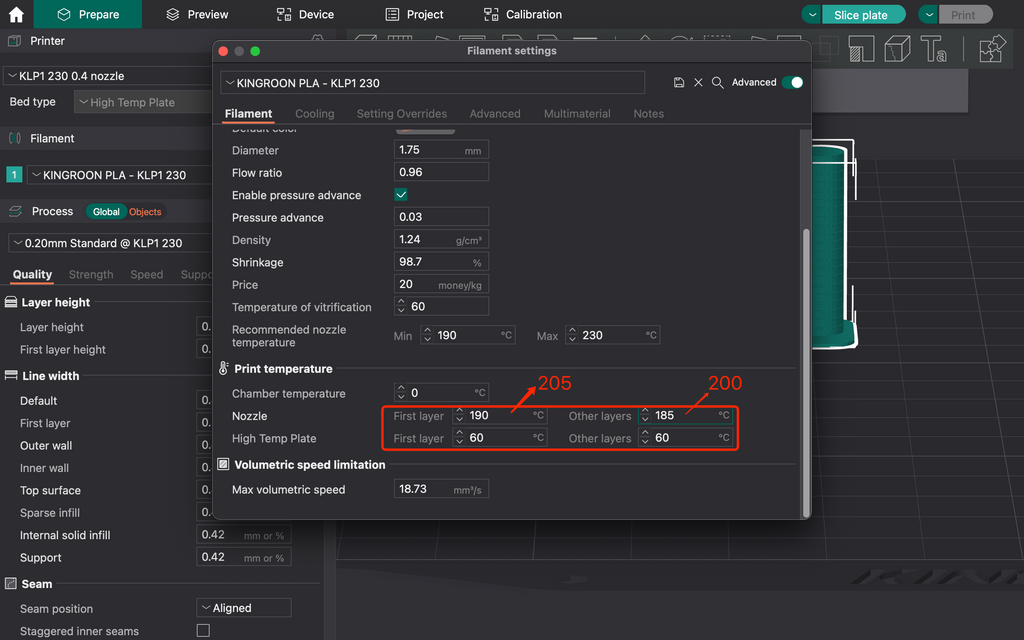

Temperature Settings

For those who downloads our OrcaSlicer Profiles, you might notice that the default temperature is 185-190, it is the average temperature that is based this tower. If you are using non-KINGROON filaments, we recommend you do this test for sure. Now, we. Need to change it to 200-205, so that we can see stringing.

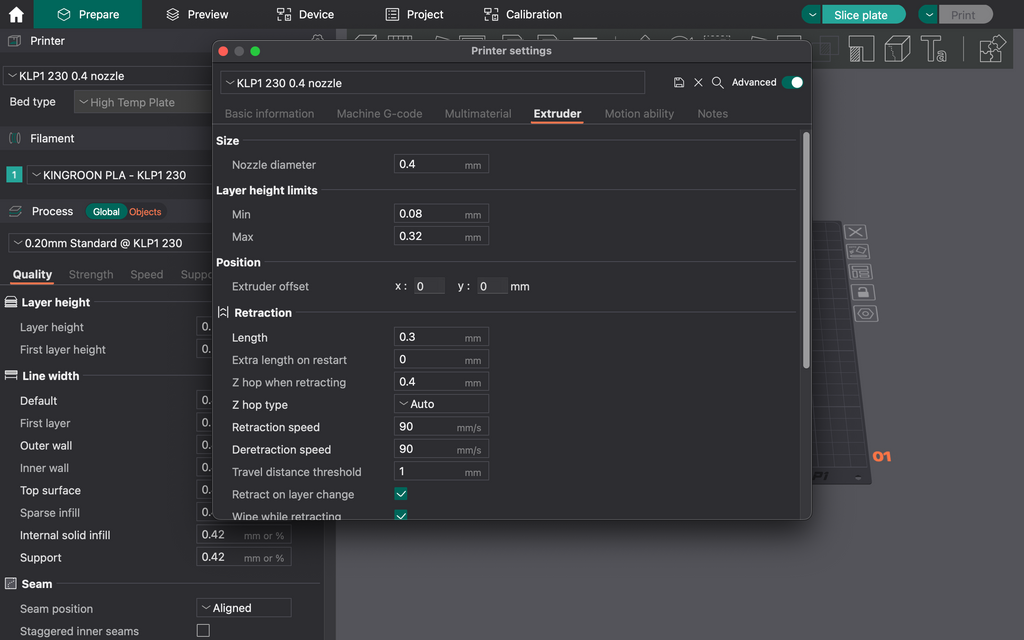

Retraction Settings

Then we go to “Extruder” and find the retraction settings. You will find my mentioned settings. Let’s keep it default and consider it as a base line.

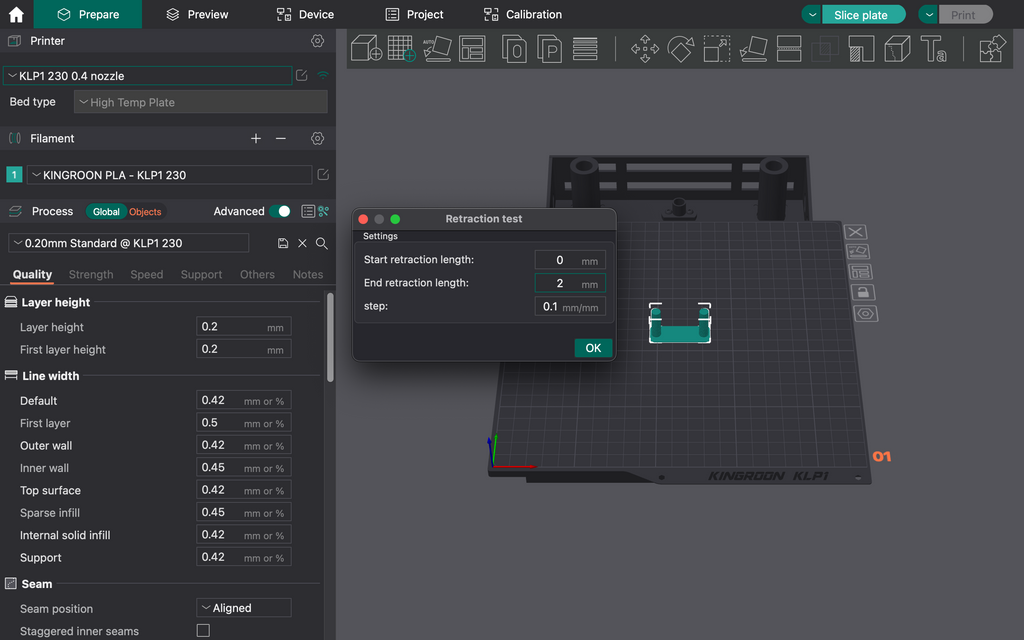

Retraction Test

The retraction test is another powerful function OrcaSlicer has. Just one click, it gets everything set up, that why we don’t have to change the retraction distance. We use the default 2cm for the test. The Bowden tube ones should be 7-6.5cm.

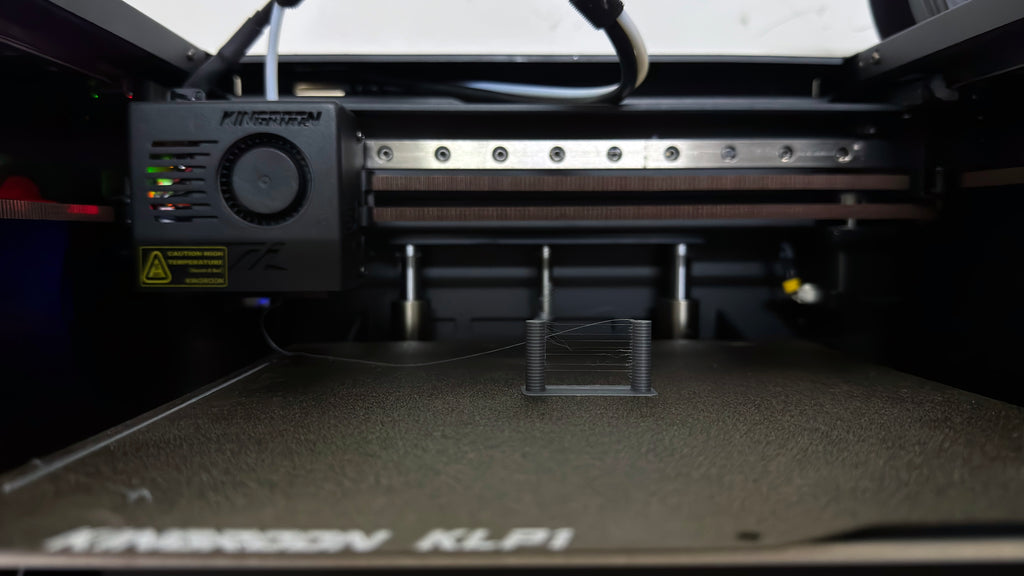

Base Line Test

The base line test shows obvious stringing when we rise the temperature to 200-205.

(Retraction Test under 200 nozzle temperature, retraction speed at 90mm/s)

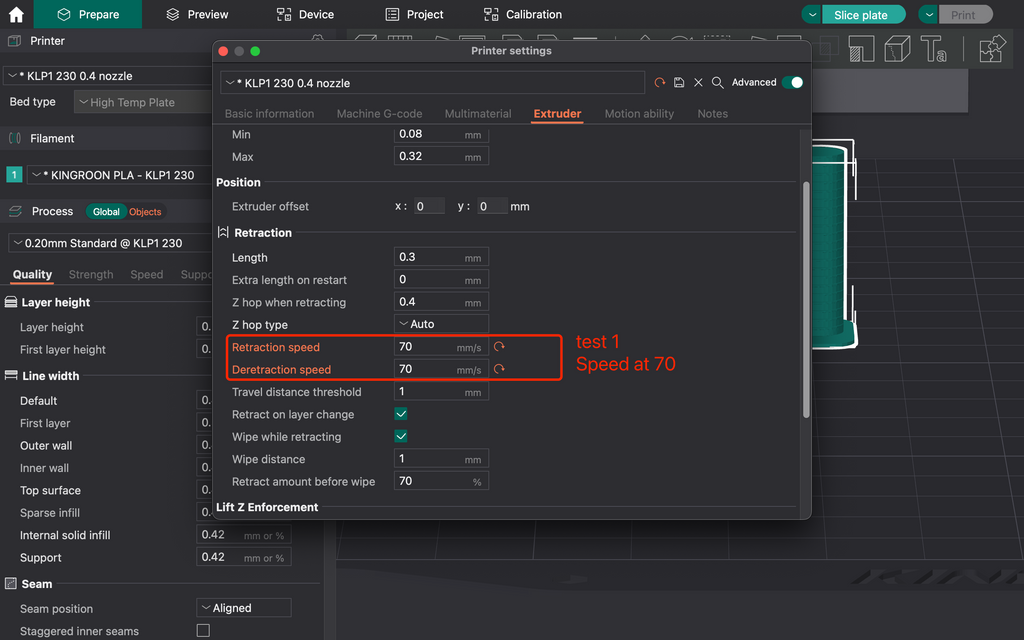

Test 1

After that, we change the retraction Speed to 70mm/s.

But we cannot tell much change.

(Retraction Test under 200 nozzle temperature, retraction speed at 70mm/s)

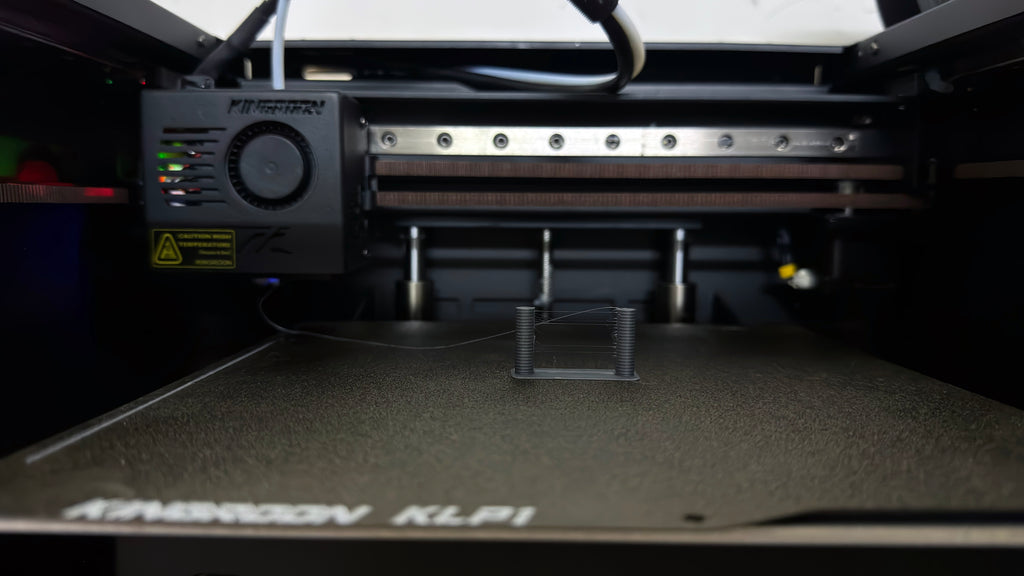

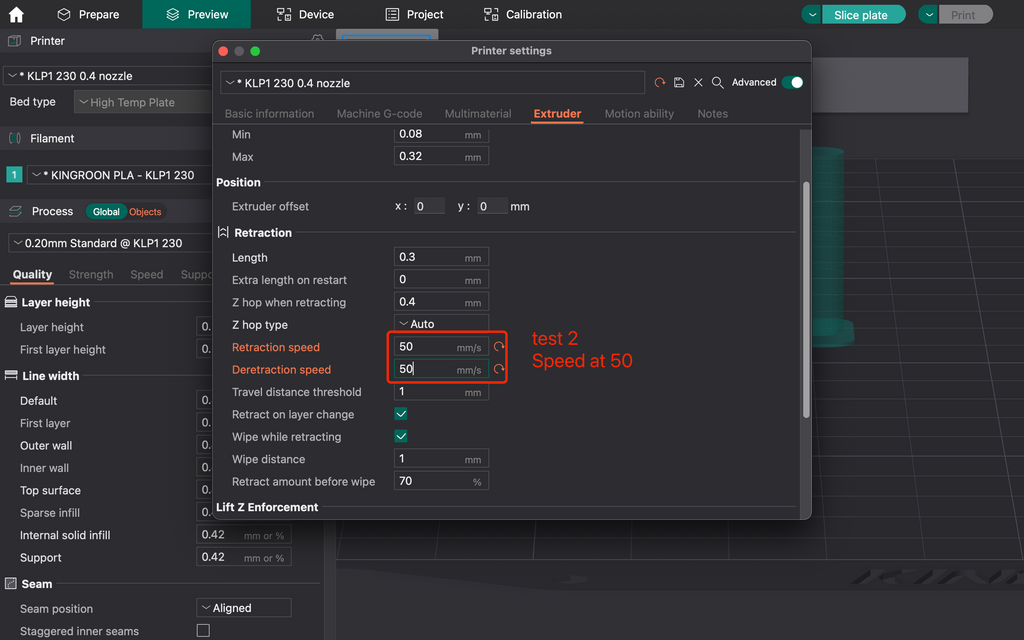

Test 2

Let’s see what changes at 50mm/s

But weird thing happened, stringing issue getting worse. It should be reduced after we are closer to 30mm/s. But not.

(Retraction Test under 200 nozzle temperature, retraction speed at 50mm/s)

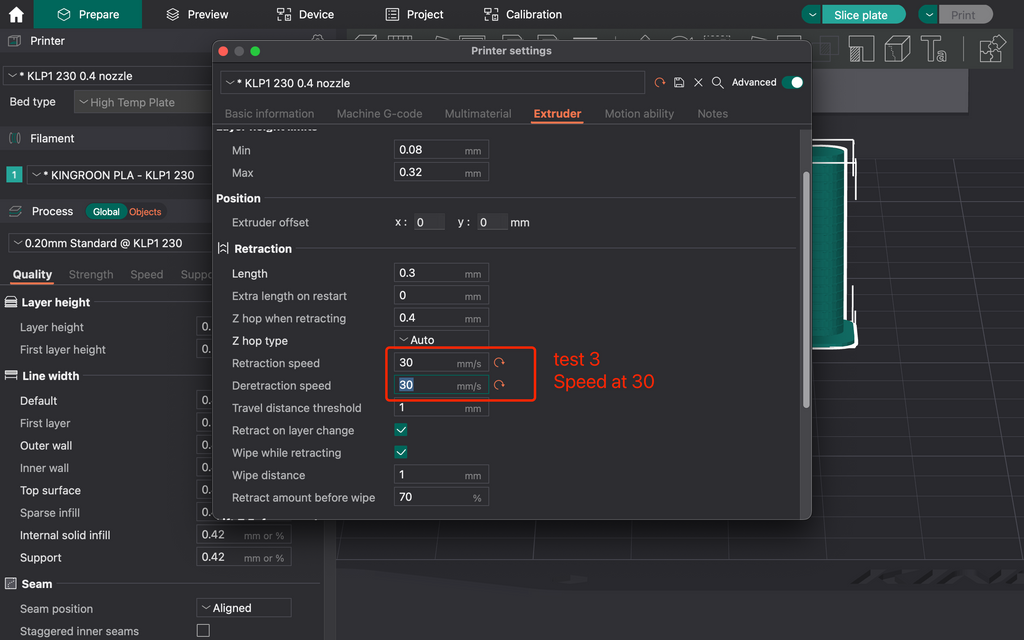

Test 3

So, I change the retraction speed to 30mm/s and wondering if I can see any magics.

But no, the stringing doesn’t fit my guess. I really thought 30mm/s would be the best settings. I can hardly tell the difference.

(Retraction Test under 200 nozzle temperature, retraction speed at 30mm/s)

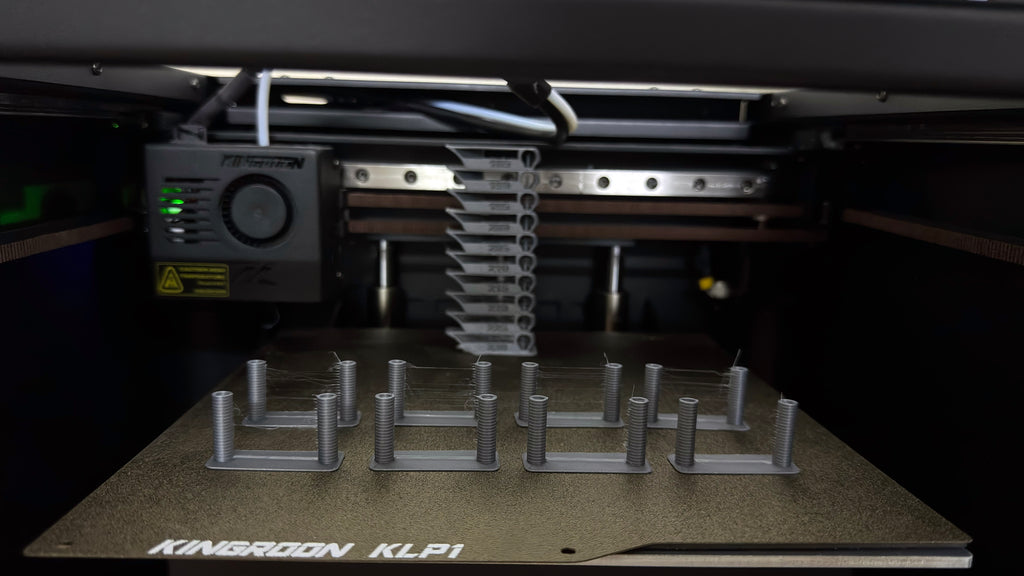

The results have no regular at all. It doesn’t make sense if the retraction speed affects stringing so much.

In case I made any mistake or missed something, I switched the temperature setting to 195-200 and did another round. But no change at all.

(Retraction Test under 195-200 nozzle temperature, retraction speed at 30-90mm/s)

I guess everyone can see the front group does have less stringing, yes, they were printed at the temperature of 195. But they change nothing. The whole test cannot prove that retraction speed affects stringing. Only retraction distance, print temperature and the filament quality matters.

To be convinced and in case I did make some mistake or missed something, here is all the referenced photos and g-code files. https://drive.google.com/drive/folders/1_BE9idTRiCTO7plSD0oDQAExaUOlcjUz?usp=sharing